How sputtering / sputter tinted film produce? What are the benefits of sputtering tinted film in the car, house or commercial windows?

Various industries employ sputtering, a physical vapor deposition (PVD) process, including its use in the production of sputter-tinted films. Here’s an overview of the sputtering process and the benefits of sputter-tinted films for different applications:

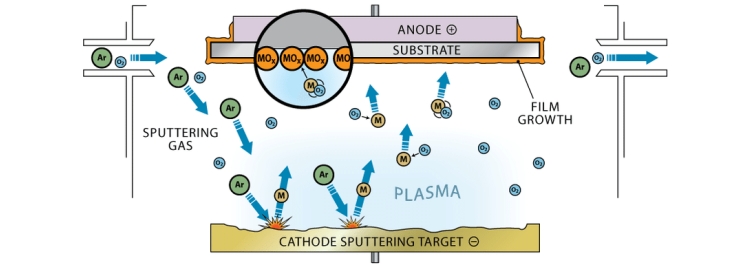

Sputtering Process:

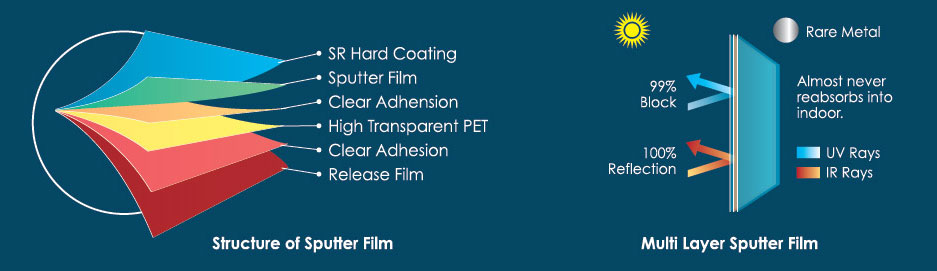

Target Material: The sputtering process begins with a target material, typically a metal or compound, such as aluminum or titanium. Operators select the target material based on the desired properties of the film.

Vacuum Chamber: In the sputtering process, operators place the target material in a vacuum chamber alongside the substrate (a film or glass sheet) intended to receive the sputtered coating. They then evacuate the chamber to create a low-pressure environment.

Ionization: A low-pressure gas, such as argon, is introduced into the chamber. The gas is ionized by applying a high voltage, creating a plasma.

Sputtering: The positively charged ions from the plasma are accelerated towards the target material. When the ions collide with the target, they transfer their kinetic energy to the target atoms. As a result, atoms from the target are ejected and deposited onto the substrate, forming a thin coating.

Film Formation: The ejected atoms travel through the vacuum chamber and condense onto the substrate, forming a thin film. By controlling the process parameters, such as gas pressure, voltage, and target material, the film’s properties, such as thickness and composition, can be precisely controlled.

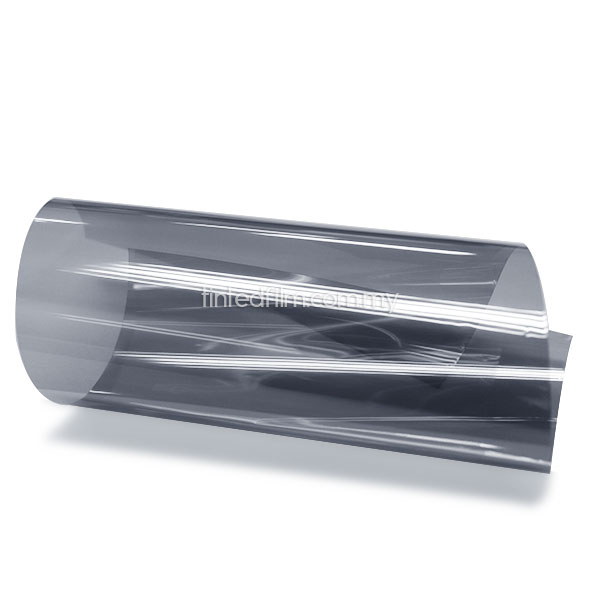

Buy Sputter Tinted Film

Benefits of Sputter-Tinted Films:

Heat Rejection: Sputter-tinted films significantly reduce solar heat gain by reflecting a substantial amount of the sun’s energy, which helps keep the interiors of cars, homes, and commercial buildings cooler, reduces the reliance on air conditioning, and saves energy.

Glare Reduction: Sputter-tinted films can reduce the amount of glare entering through windows, improving visibility and comfort for occupants. This is particularly beneficial in vehicles and commercial spaces where excessive glare can be distracting and uncomfortable.

UV Radiation Blockage: Sputter-tinted films typically achieve a high level of ultraviolet (UV) radiation blockage. They block a significant portion of harmful UV rays, which helps protect the occupants and prevent fading or damage to interior furnishings, such as upholstery and carpets.

Privacy and Security: Sputter-tinted films can provide privacy during the daytime by making it difficult for outsiders to see inside the vehicle or building. Additionally, these films can enhance the shatter resistance of glass, providing an added layer of security against break-ins and accidents.

Optical Clarity: Scientist create sputter-tinted films to maintain good visibility and optical clarity. They allow natural light to pass through while reducing heat and glare, ensuring that the view from inside and outside is not compromised.