What is 2ply Dyed Tinted Film? Manufacturing Process, Advantages, and Disadvantages

In the world of automotive and architectural window films, 2-ply dyed tinted film has emerged as a popular choice for those seeking a perfect blend of style, privacy, and UV protection. In this blog post, we will delve into the fascinating realm of 2-ply dyed tinted film, exploring its manufacturing process and weighing the advantages and disadvantages that come with this innovative window film technology.

Manufacturing Process: How is Dyed Tinted Film Made?

Dyed tinted film is a type of window film that undergoes a unique manufacturing process to achieve its distinctive properties. Here’s a brief overview of how 2-ply dyed tinted film is typically made:

- Polyester Base: The process begins with a high-quality polyester base, which serves as the foundation for the window film. This base is crucial for the film’s durability and optical clarity.

- Dyeing Process: The polyester base is then treated with a specialized dye solution. This dye is responsible for giving the film its tinted appearance. The dyeing process is carefully controlled to ensure uniform color distribution and optimal light transmission.

- Adhesive Layer: After dyeing, a layer of adhesive is applied to the dyed polyester. This adhesive layer allows the film to adhere securely to glass surfaces when installed.

- Scratch-Resistant Coating: To enhance durability and longevity, a scratch-resistant coating is often applied to the outer surface of the film. This coating helps protect against everyday wear and tear.

- Lamination Process: In the case of 2-ply dyed tinted film, two layers of dyed and treated polyester are often laminated together. This enhances the film’s overall strength and performance.

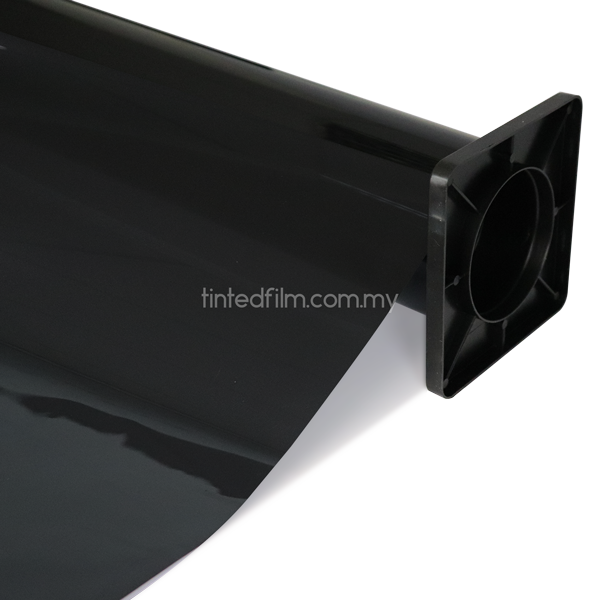

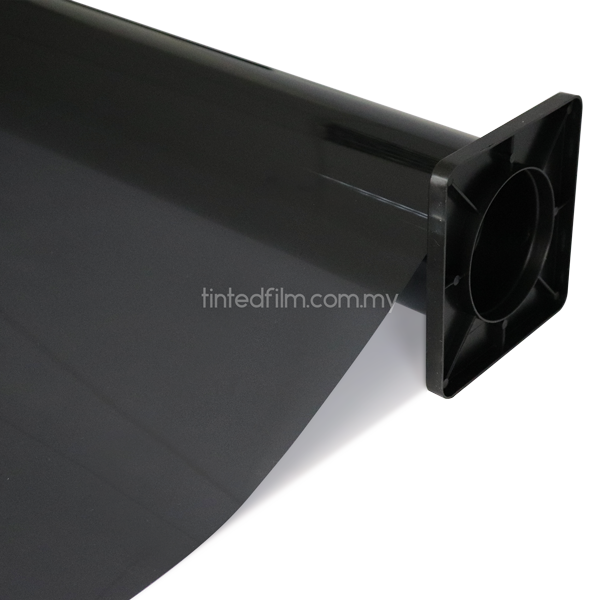

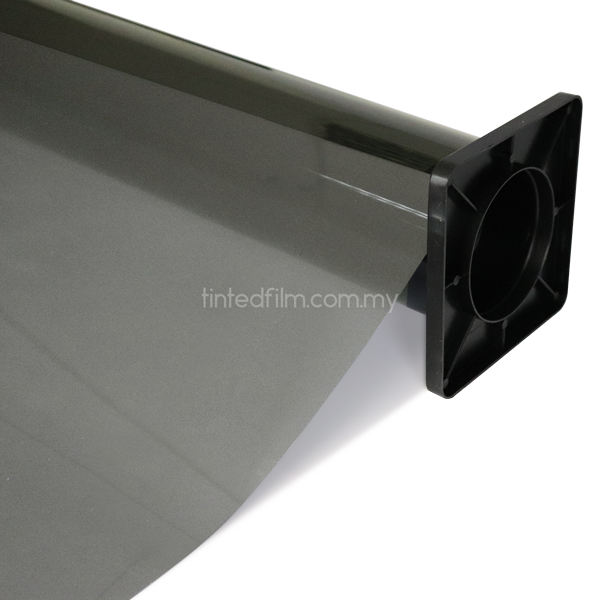

2ply Dyed Tinted Film

Now that we’ve unveiled the manufacturing process, let’s explore the advantages and disadvantages of 2-ply dyed tinted film.

Advantages of 2-Ply Dyed Tinted Film:

- Enhanced UV Protection: Dyed tinted film is effective in blocking a significant amount of harmful UV rays, protecting occupants and interiors from sun damage.

- Improved Aesthetics: The tinted appearance of the film adds a touch of elegance and style to vehicles and buildings, enhancing their overall aesthetic appeal.

- Privacy: Dyed tinted film provides an increased level of privacy by reducing the visibility into the interior space while maintaining clear outward visibility.

- Affordability: Compared to other types of window films, dyed tinted film is often more budget-friendly, making it an attractive option for cost-conscious consumers.

Disadvantages of 2-Ply Dyed Tinted Film:

- Fading Over Time: One of the drawbacks of dyed tinted film is that it may experience gradual fading over time, especially when exposed to prolonged sunlight.

- Heat Absorption: While the film provides some heat reduction, it is not as effective in blocking heat as other types of window films, such as ceramic films.

- Limited Heat Shrinkage Ability: Dyed tinted film may have limited heat shrinkage ability during the installation process, making it more challenging to apply on curved or complex surfaces.

- Potential for Bubbling and Peeling: In certain conditions, dyed tinted film may be more prone to bubbling or peeling, especially if the installation is not performed by a professional.

2-ply dyed tinted film offers a compelling combination of style, UV protection, and affordability. Understanding its manufacturing process and weighing the advantages and disadvantages can empower consumers to make informed decisions when choosing window films for their vehicles or buildings. Whether you prioritize aesthetics, privacy, or budget considerations, dyed tinted film remains a versatile option in the world of window film technology.